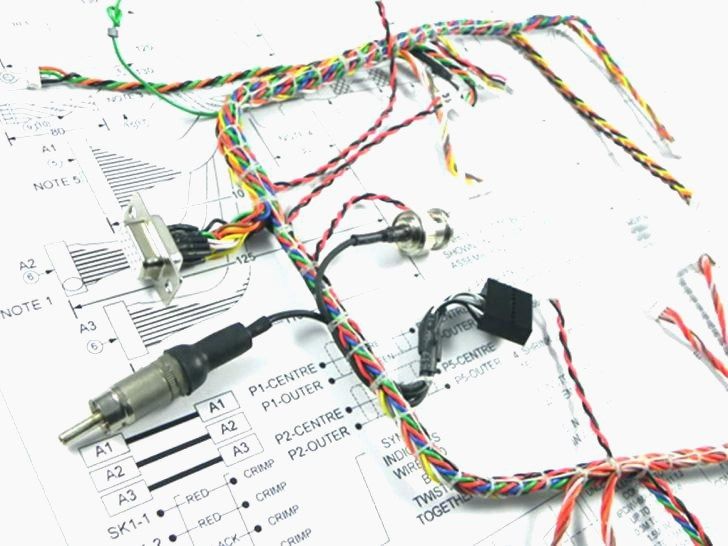

Prefabricated Wire Harnesses

Why World Cord Sets?

In a controlled enviornment, productivity and accuracy are significantly higher. By prefabricating in a workspace designed for the project, the quality of the wire harness will increase with cost savings.

No matter the industry, Project Managers can all relate on one topic: Project Scheduling and Deadlines. Managing, optimizing, and routing dozens of small wires can create inconsistancies in your products and delay in production. Installing a prefabricated wire harness can be an easily planned task that can free up your production line, spec in World Cord Sets to your next project!

World Cord Sets has been custom designing and fabricating power solutions for the majority of Data Centers in the United States for over a decade and a half. This existing knowledge and experience allows us to create custom tailored solutions for all of our customers, paired with systems and processes that keep our prices low to create a realistic solution for our customers. By partnering with our experienced engineering and assembly teams, you can keep your staffing low and leave the headaches to us.

Rather than occupying your company resources in a fabrication warehouse, manufacturing equipment, and dedicated assembly employees your team can focus on your projects at hand when sourcing these tasks. We have a dedicated assembly staff with an optimized assembly area that focuses on consistancy, efficiency and quality.

All of our assembled products undergo rigorous visual inspections as well as continuity testing to ensure your end product or installation will be safe. We utilize state of the art Remove of Outer Jacket (ROJ) and Strip Machines that are programmed to specific lengths and diameters to reduce user error and reduce the loss of copper strands upon stripping of the conductor jacket.

For large quantity and repeat orders, we also offer China Assembled Wire Harnesses that are assebled overseas for an even larger cost savings. Once our engineering team has ironed out our proccesses to fabricate your wire harness and cleared the design with your Project Managers, we work closely with our partners overseas to provide the most cost effective solution for your projects wire harness components.

World Cord Sets has always strived to remain competitive in an ever changing market. Our return customers continue to return to us for prefabrication because of the quality,consistancy and competitive pricing we provide year after year. Contact our sales team today and get a quote for your next project, and realize the saving your team can acheive by sourcing your Wire Harness Prefabrication with World Cord Sets.

Our Engineering team works closely with your team reviewing design drawings to identify break out points, constrictions, etc. They then create a prototype design for your team to review. Once both teams have agreed upon a design, we send the plans to our assembly team with over a decade of power assembly experience. We have experience in applications such as large quantity manufacturing quick disconnects, and internal electrical connection components. We work directly with manufacturers and provide cost efficient components to spec.

Between the checks and balances we have incorporated into our assembly procedures, and our experienced assembly team with a keen eye for detail you can rest assured that sourcing through World Cord Sets will be a reliable and economical way to alieviate assembly work from your team.

Customer

Support

Downloadable

Documentation

Quality

Assurances

100%

Customization

Industrial Wire Harnesses can encompass a wide variety of industries, with unique standards for each pertaining industry. World Cord Sets offers a cost effective and reliable solution to unique enviornment challenges. We provide solutions that can be scaled for large ongoing projects, and custom tailored specs that can fit unique challenges that the demanding, and time sensitive Industrial Industry demands.

Our experience includes applications in Manufacturing Equipment, Industrial Plants, CNC Machines and much more. Checkout our Industrial Wire Harness Page to explore the options and solutions that World Cord Sets can provide for you.

Customer

Support

Downloadable

Documentation

Quality

Assurances

100%

Customization

Whether you are working on an interior design for your home or for a client, powering devices throughout the room without having extension cords running left and right is important for aesthetics and creating a comfortable/clean space. No matter the size of the project, our team can work with you to design a custom tailored solution to provide power from the available sources, in the most cost effective way.

Our experience includes applications with custom extension cord cable assemblies, premade office data and power cable harnesses, and applications of concealing power cables in both office and home enviornments. Customers are often suprised at how inexpensive a custom cable assembly can be, and how much more value they get from a custom tailored power or data option. We are able to offer such inexpensive, superior solutions because we are also a cable whole saler with thosands of cables available and an assembly team already in place to complete your order.

Customer

Support

Downloadable

Documentation

Quality

Assurances

100%

Customization

World Cord Sets has been a key player in supplying the power cords for some of the biggest data center projects in the US to date. Along the way we have grown acustom to what our customers (Data Center Installation Contractors) are looking for and how to make the installation process as frictionless as possible. Our engineering team will work directly with your team's Project Manager(s) to understand the layout of your power sources and rack layouts. With this knowledge our team can design premade data and power cable trunks for your next installation.

Pre Assembled Power and Data trunks can save days on installation, as well as free up your jobsite allowing other contractors to get their work done rather than taking up prime real estate trying to optimize the wire tray routing the data and power cords. We even offer custom labeling on each cable end to make installation of the cables/ premade trunks straight forward and timely.

Customer

Support

Downloadable

Documentation

Quality

Assurances

100%

Customization

Precise specifications, High Security Manufacturing, Accurate Timelines and Competitive pricing come with every World Cord Sets quote. We specialize in harnesses that are built to survive harsh, wet environments with high vibrations, temperature and winds. If you are a military contractor currently utilizing the United States Government acquisition website, we also are a registered vendor on all neccisary websites such as SAM, FBF and GSA.. Wolrd Cord Sets conforms with all neccesary procedures and regulations required to do buisness with the government, including the Federal Acquisition Regulations and the Defense Federal Acquisition Reulations Supplement (DFARS).

We design wire harnesses for everything from personnel carriers (APCs) to infantry and cargo vehicles. From Humvees, ATV and SUVs to Armored Vehicles, we design high quality wire harnesses with the highest quality connectors that will withstand the elements. All of our harnesses are manufacturered in the US and we are proud to aid all branches of the United States Armed Forces. Click on the link below to discover all of our capabilities and compliance paper work for government contracts.

Customer

Support

Downloadable

Documentation

Quality

Assurances

100%

Customization

Telecom and Datacom cables, like DS0, DS1, DS3, DS4, fiber, coax, and ethernet are all neccisary for Communications, but can often times become a tangled mess. World Cord Sets offer both custom made cables, and wire harnesses for these applications. Our team of engineers have many years of experience sourcing, installing, and untangling cables. This line up of trials have fostered solutions that we use on every custom made Telecommunication wire/cable harness. Our partnerships with reputable manufacturers allows for us to provide the most cost effective solution for your data cable harness.

Browse our examples of Telecom and Datacom wire harnesses and cables, with a detailed description of the customer service and quality of work you can expect when choosing World Cord Sets. Click below and learn more!

Customer

Support

Downloadable

Documentation

Quality

Assurances

100%

Customization