Fiber Optics: Choosing the right Ferrule Polish

Created on: Jun 5, 2019

Fiber Optic Ferrule Polish

When deciding which fiber optic cable is best for you, there are many factors that may seem overwhelming. Especially when each option comes with its own set of acronyms and pros/cons to consider. This blog post is made with the intention of educating you about an important factor of fiber optic connectors; the ferrule polish. Before we dive into the options available, it is important to define two important terms that pertain to this topic.

Important Terms:

Ferrule:

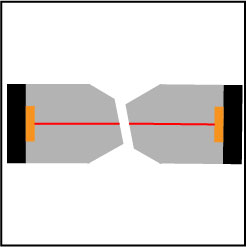

The ferrule is the housing for the exposed end of the fiber, designed to be connected to either another cable, or into a transmitter or receiver. The ferrule is encased in the connector, and the tip is exposed to be mated against another ferrule at the point of connection. When ferrules are mated with one another, the light should pass from one fiber to the next, with minimal loss of light (attenuation). Ferrules primarily are made of ceramic due to their exceptional environment resilience, however they also come in glass, plastic and metal. As fiber optics increased in efficiency, engineers started upgrading the surface of this critical point of attachment. This is where polishing techniques were introduced.

Ferrule Polish:

The ferrule polish is the manipulation of the end-face to create various form-fits between the two ferrule tips. As time passed, field data helped guide engineers to come up with better mating styles that would decrease the loss of light. Several standard Polish styles including Flat Fiber, Physical Contact, Ultra Physical Contact, and Angled Physical Contact which have been defined by precise geometric parameters to increase the efficiency of the data transfer.

Ferrule Polish Types:

Now that we have defined the two important terms, we can go through the evolution of ferrule polish types and the pros and cons of each one to help you determine the best fit for you fiber needs.

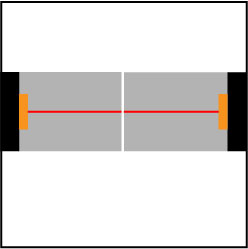

Flat Fiber

The Flat Fiber Style is just as the name suggests, the tip of the ferrule is flat which proved to be ineffective. The flat and larger surface area creates a small air gap between the connecting ferrules which causes some light to reflect back towards the source, known as Optical Return Loss (ORL). Engineers took this as a learning curve and the created a refined ferrule tip known as the Physical Contact Connector. The Flat Contact Polish style has since been outdated.

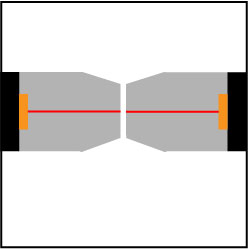

Physical Contact

The Physical Contact connector has a slightly cylindrical cone head that was intended to reduce the air gap flaw with the Flat Fiber Connector, this is commonly found on older generation pre-made OM1 and OM2 single mode fiber. Eventually the design was modified to decrease surface area even more, creating the ultra physical contact connector. Since OM1 and OM2 fiber is not generally used in new installation, this style of polish is outdated however for retrofitting older connections, the UPC polish style will mate with this PC polish style.

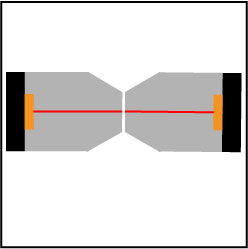

Ultra Physical Contact

The Ultra Physical Contact Connector is the standard ferrule polish type for most applications. The design builds off of the PC style, but with a small surface area and tighter cone head shape. This reduced the ORL compared to its predecessor the PC. The main limiting factor of the UPC is that the quality of the fiber surface degrades every time it is mated/unmated, creating more imperfections in the surface of the end-face. This will create larger and larger air gaps that reflect light and increase the ORL. The beauty of the UPC polish is that it is perfect for retrofitting, and can mate with FC, PC and other UPC ferrule tips. If you are buying pre-made fiber jumpers, it is likely you are going to be choosing between this option and the final option, the angled physical contact connector. We offer various Single and MultiMode Fiber options that utilize the UPC style polish.

Angled Physical Contact

The Angled Physical Contact Connector has an angled tip that has the lowest back reflection of all the options listed. It can also withstand more mating/unmating than its predecessor, the UPC. The APC generally has a return loss of -60dB, while the UPC has -50dB followed by the others. This style ferrule polish is commonly found on highly sensitive test equipment or on radio devices with a sensitive signal.

Conclusion

With all of the advancements in fiber technology, there are many different options available to fit your specific requirements. If you wish to learn more about the Limiting Factors of Fiber Optics to better educate yourself before making any buying decisions, feel free to check out our article on the topic. With the knowledge you now have of the the different polish styles, which one will you choose?

Author:

Brian Sackett

Marketing & Development