Fiber Optics: Cable Jacket & Fire Rating

Created on: Jun 17, 2019

Fiber Optic Cables are incredible data transfer mediums with a very fragile core. The fiber cables are built inside out, with everything based around protecting and enhancing the core. The Outer Jacket is designed as a barrier for moisture, mechanical, fire, and chemical defense. In this article, we will review the different Jacket Materials, Color Codes, Fire Ratings, and Purpose Ratings.

Important Terms

Plenum - an Area in a building used for air flow/ distribution such as a drop ceiling or raised floors. This is most common in commercial settings.

Riser - an Area in a building such as a shaft, duct, etc. that runs vertically through the building and passes through one or more floors.

General Purpose- all other areas of the building that are not Plenum or Riser.

Fiber Optic Jacket Materials

There are many different options for fiber optic jacket types. The biggest consideration is the environment of use, as there are different codes pertaining to permitted uses for certain materials.

| Jacket Material | Notes |

| PVC (Polyvinyl Chloride) | PVC is a cost effective, flexible and robust material that is flame/oil resistant. This makes the PVC jacket usable Indoor and Outdoor, which is the reason this is the most common jacket material. |

| PE (Polyetheylene) | PE has the best moisture/weather resistance, and is abrasion resistant. This is the reason the PE is the standard for outdoor fiber optic cables. |

| PVDF (Polyvinyl Difluoride) | This is used for Plenum applications because it is more fire-retardant than Polyetheylene, and produces less smoke. |

| LSZH (Low Smoke Zero Halogen) | LSZH jacket emits low smoke and no halogenated gas when burned. These can be toxic to humans and expensive IT equipment. This jacket has a rigid matte rubber feel, and is the most expensive jacket material. This is commonly used in government facilities, or plenum applications. |

Jacket Color Code

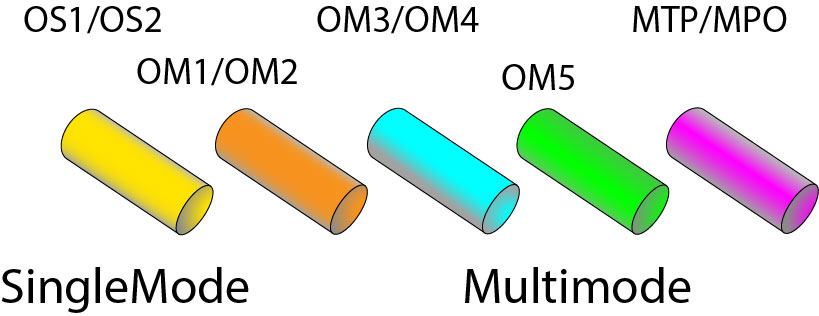

All Fiber Optic Color codes are according to the EIA/TIA-598 and define the different fiber types. Single Mode Fiber is usually yellow, Multimode Fiber comes in Orange(OM1 and OM2), Aqua(OM3 and OM4) and Lime Green(OM5). Certain manufacturers have also defined MTP trunk cables by a magenta jacket. For outside, industrial plant locations, the standard jacket color is black.

Cable Fire Rating

Under the National Electrical Code, there are 8 levels of fire resistance for both non-conductive and conductive cables. Indoor cables must be marked visibly and installed per their listed use. An important thing to note is the substitutional hierarchy of the fire ratings. Plenum Rated cable can be used for Plenum, Riser, and general purpose. Riser Rated cables can be used in Riser and GP locations, and General Purpose can only be used for just that.

| NEC Code | Description | Cable Application |

| OFNP | Optical Fiber Non-conductive Plenum Cable | Plenum, Overhead , Fiber Only |

| OFCP | Optical Fiber Conductive Plenum Cable | Plenum, Overhead, Fiber/Wire |

| OFNR | Optical Fiber Nonconductive Rise Cable | Riser, Data Center Backbone, Fiber Only |

| OFCR | Optical Fiber Conductive Rise Cable | Riser, Data Center Backbone, Fiber/Wire |

| OFNG | Optical Fiber Nonconductive General-Purpose | General Purpose, Horizontal installation |

| OFCG | Optical Fiber Conductive General-Purpose | General Purpose |

| OFN | Optical Fiber Nonconductive | General Purpose, Horizontal, Fiber Only |

| OFC | Optical Fiver Conductive | General Purpose, Horizontal, Fiber/ Wire |

Author:

Brian Sackett

Marketing & Development